Food & Beverage Manufacturing faces several challenges, including manual processes, paperwork, and siloed data that lead to inefficiencies, errors, and compliance issues. These issues can make it difficult for manufacturers to meet quality standards, keep up with consumer demand, and remain competitive in an increasingly demanding market.

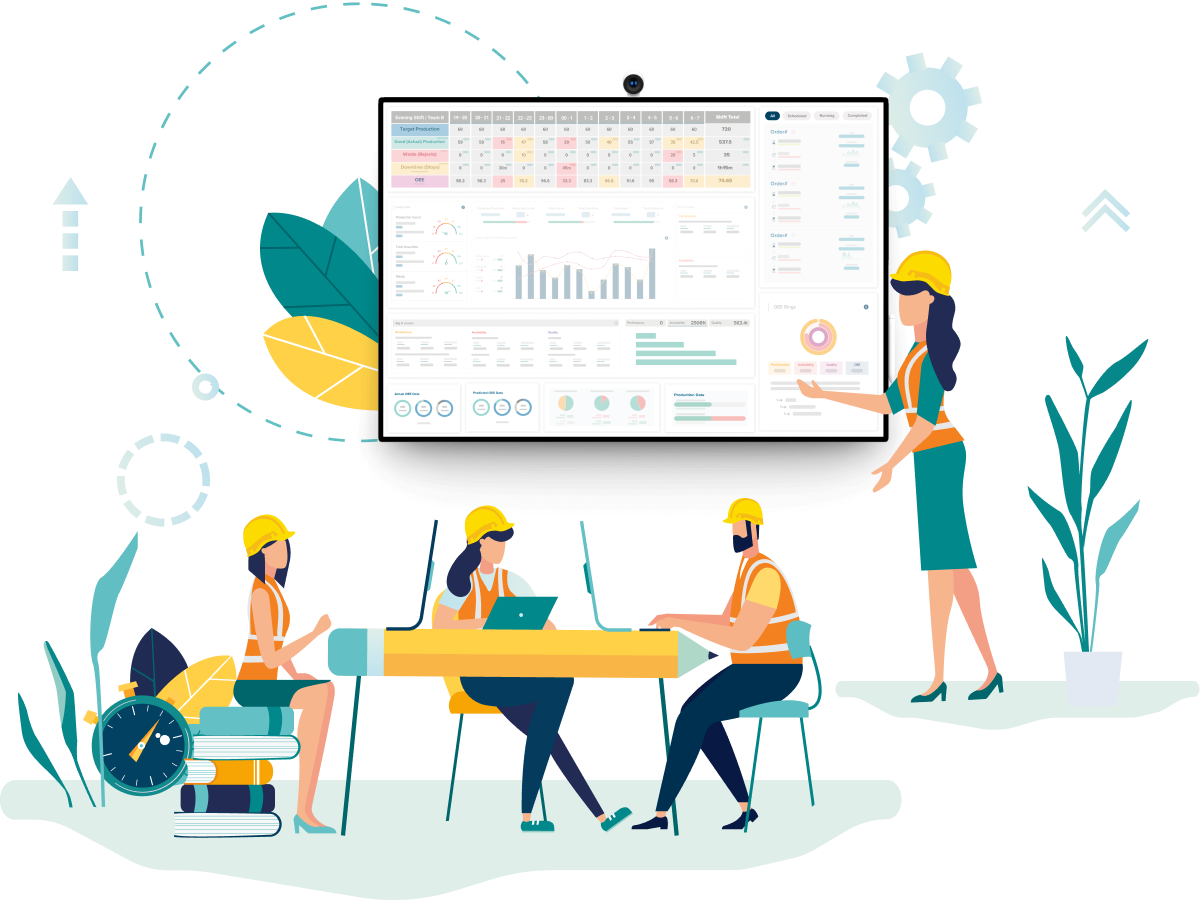

IfElseCloud MES is a comprehensive software solution that addresses these challenges and optimizes Food & Beverage Manufacturing processes. With IfElseCloud MES, manufacturers can improve OEE, improve quality, reduce downtime, remove paperwork, and automate reports. It enables manufacturers to use advanced technologies like ML and AI to monitor and improve processes, digitalizes the manufacturing processes, and attract a younger workforce.

IfElseCloud MES is a vital tool in advancing Food & Beverage Manufacturing and enabling the industry to embrace digital transformation and Industry 4.0 concepts. With IfElseCloud MES, manufacturers can gain end-to-end visibility and control over their supply chain, optimize resources, and achieve greater agility. Ultimately, IfElseCloud MES is a key step in progressing toward Smart Industry Readiness and driving innovation in the Food & Beverage Manufacturing industry.

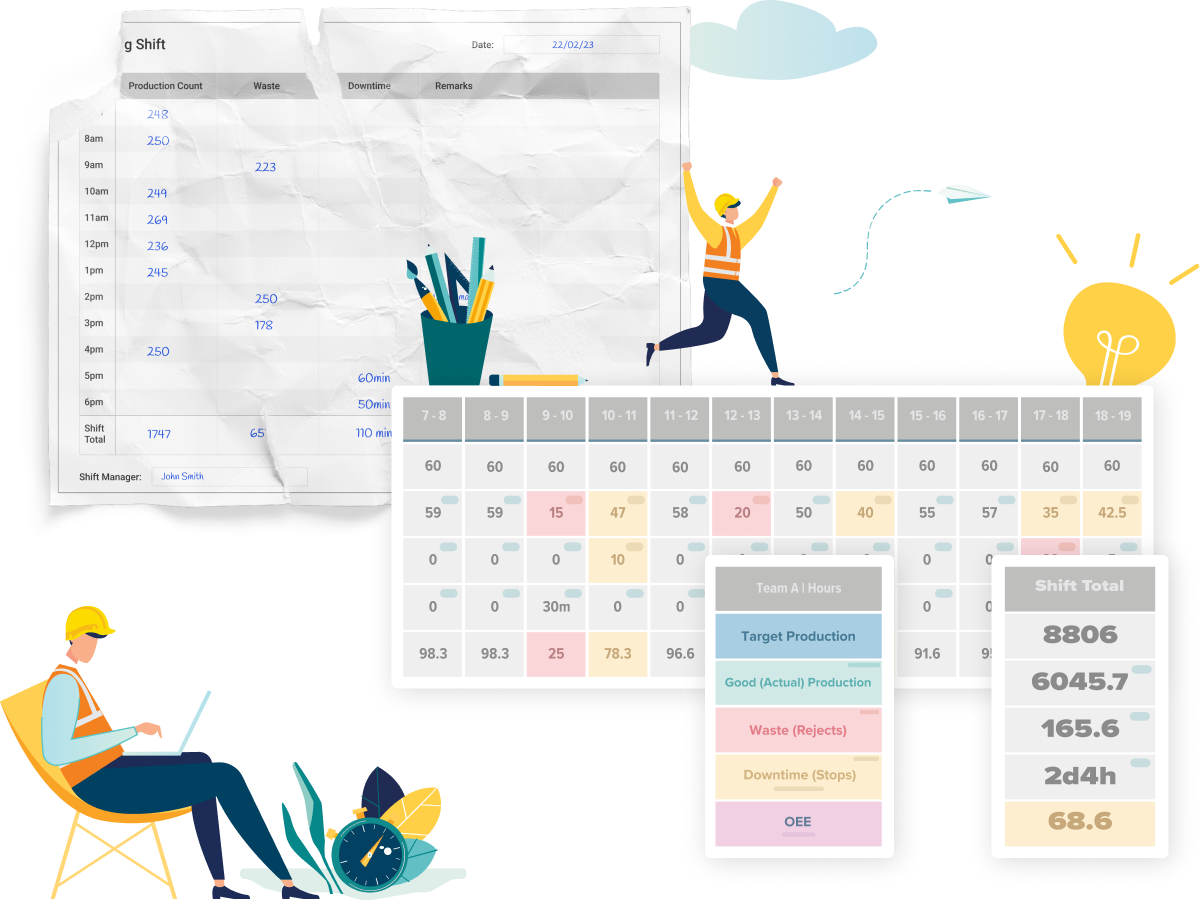

In today's digital manufacturing age, relying on paper-based systems to manage operations can leave at a disadvantage. Smart MES apps can help upgrade workflows, improve communication, and enable better collaboration across teams.

Embrace the future of manufacturing by adopting advanced MES technologies and digital techniques to stay ahead in a rapidly evolving industry.

Integrating cloud and industrial tech improves safety, quality, and compliance while reducing costs and waste with our MES.

Regularly reviewing production processes is crucial to staying up to date with the latest MES technologies.

Data-driven decision-making using modern MES is a continuous process that helps stay agile, innovative, and stay competitive.

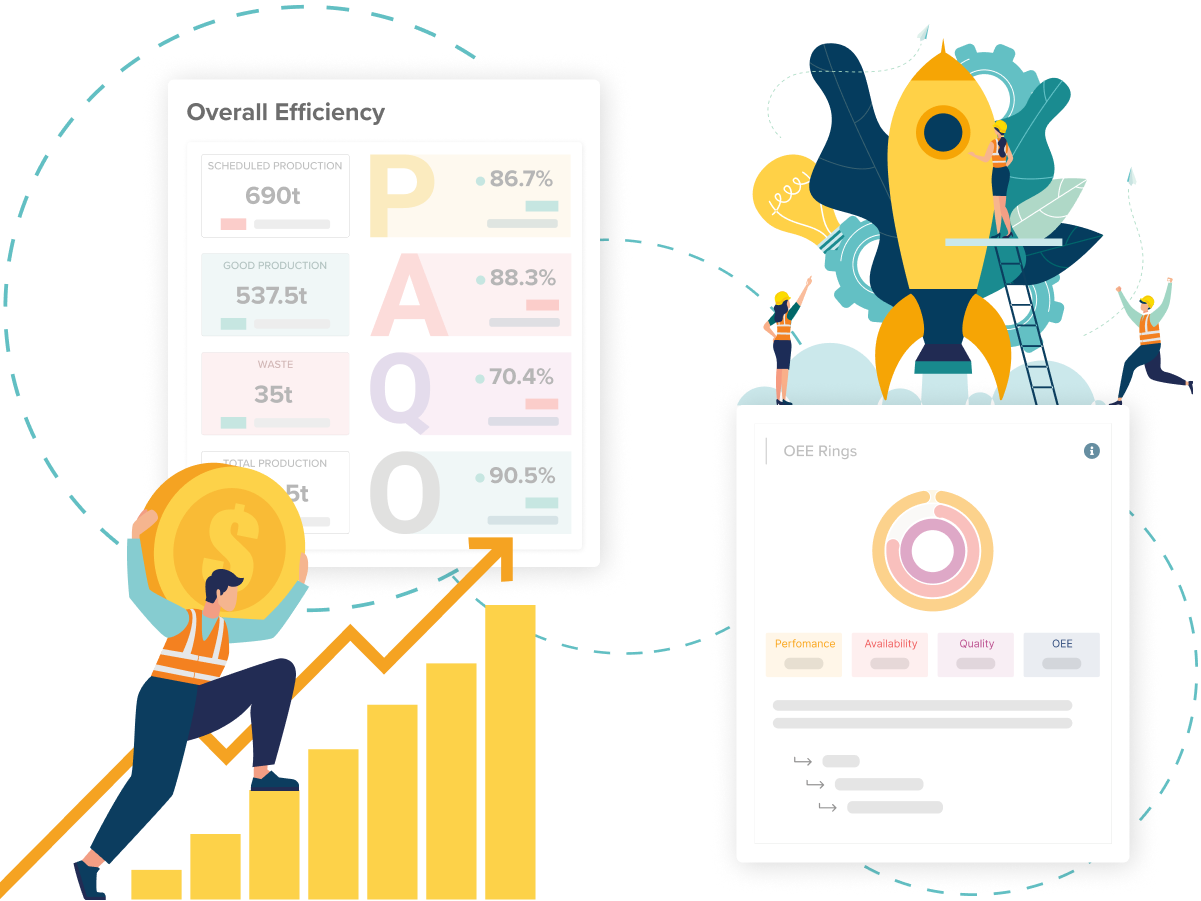

By optimizing your operations for performance, availability, and quality, you can improve your bottom line, enhance your customer experience, and unlock new opportunities for growth with the help of modern MES.

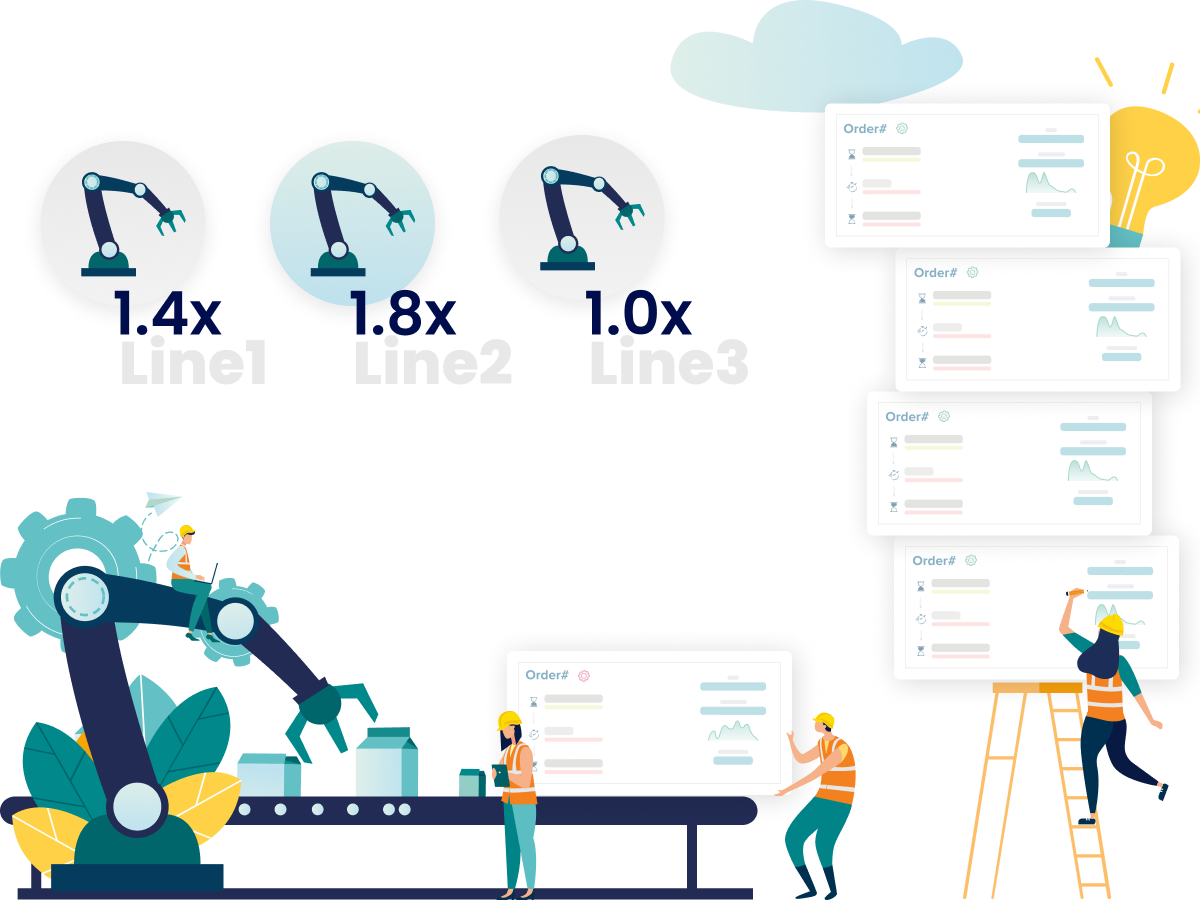

Better modern MES line efficiency monitoring can respond quickly to changing market conditions.

Bird's eye view of operations, enabling quickly identify issues and opportunities with our modern MES.

With our modern MES optimize production processes for better efficiency and profitability.

Reduce costs associated with equipment downtime and repair with our digital MES failure reason dashboard.

To attract younger workers, manufacturers need to embrace next-gen MES tech and ditch paper-based processes. This can lead to improved efficiency, productivity, and employee satisfaction with digital manufacturing.

With our MES, store and manage digital documents more efficiently, making it easier to find and retrieve information without any use of paper.

Younger workers value diversity in the workplace, Modern MES creates a diverse digital manufacturing culture.

With a renewed MES focuses on innovation and creativity, the outlook for manufacturing is bright, with the potential for breakthroughs.

With our Mobile MES accessibility enables workers to access critical information and tools from anywhere, at any time.

With advanced manufacturing execution systems analytics and real-time monitoring, manufacturers can optimize their asset performance, leading to improved equipment availability, utilization, and reliability in your food and beverages industry.

Our MES enables businesses to predict issues, prevent equipment failure, and ensure compliance with industry standards.

Key performance indicator that can improve their bottom line by minimizing maintenance costs and increasing asset longevity.

Critical metric for determining the average time it takes to repair equipment, maintenance schedules & reduce downtime.

Valuable insights into the effectiveness of their asset management strategies, enabling optimize processes.

Our built-in smart manufacturing execution system scheduler can provide valuable insights into operations, enabling optimization of processes and enhance overall performance.

Drive efficient work order scheduling with data-driven insights, leveraging analytics and real-time information for optimized task prioritization with MES.

Variety of chart types are enable to present data in a way that is easy to understand and visually appealing with our platform.

Make quick and accurate scheduling decisions with real-time insights from effortless scheduling with the latest MES.

Connect the dots, optimize your workflows, and take your business to the next level with ERP & E-Commerce Integration.

Improve overall equipment effectiveness, reduce unplanned downtime, and enhance maintenance efficiency with automated planning and scheduling and keep machines running smoothly without any breakdowns with our advanced MES platform.

Keep assets running at peak performance with a visual maintenance planning solution that helps identify potential issues before they occur in our MES .

Effortlessly track work orders using our MES, enhancing coordination and productivity.

Keep your assets in top condition with modern MES maintenance schedules.

Ensure quick and effective repairs with concise breakdown maintenance SOPs.

Take control of production processes with the digital MES real-time reporting feature, allowing for continuous monitoring and improvement, increase overall growth and adopt digital manufacturing.

Make operations more sustainable with our digital platform, reducing paper waste and carbon footprint.

Get visibility into operations, optimize manufacturing processes with intuitive and easy-to-use MES platform.

Simplify complex business operations and empower team with data-driven insights and improve ROI with our MES.

Manage financial risk and ensure compliance with regulations through digital MES real-time reporting and analytics.

Say goodbye to silos and foster cross-functional collaboration with the digital MES centralized and transparent data platform, driving innovation, growth, and success. Adopt digital transformation in your food and beverages industry.

Eliminate data silos and optimize information sharing across teams, enhancing efficiency and productivity with our MES.

Transform your collaboration practices with our digital platform's user-friendly interface and powerful tools.

Leverage the power of inclusive collaboration to drive innovation and improve overall manufacturing process.

Unlock the full potential of your team with a continuous feedback loop that empowers individual productivity.

With the help of our digital MES, Uncover valuable insights from your manufacturing data, and use them to optimize operations, reduce waste, and drive profitability.

Make strategic decisions with confidence, leveraging data-driven insights to optimize operations and achieve maximum ROI.

Utilize data insights to identify root causes, making informed decisions that keep operations running smoothly.

Track and analyze production trends, optimizing operations for growth with our modern MES.

Implement strategies to reduce costs, minimize loss and increase profitability, leveraging data-driven insights.

Brand the MES platform with your own logo, localize language, and configure workflows to match your unique business requirements with IfElseCloud.

Personalize this MES platform to align with your manufacturing processes, from data visualization to production scheduling, for maximum value and impact.

Gain visibility into production performance with real-time KPI monitoring, improve decision-making with our MES.

Enhance user engagement and satisfaction with personalized branding and language interfaces in this MES platform.

Efficiently manage inventory, reduce waste, and minimize errors with customized SKUs and assets.

120+

Our advanced data streaming technology delivers real-time data with minimal latency, ensuring up-to-date information, helps in solving the lack of real-time visibility.

Our advanced data analytics algorithms help identify and address inconsistencies in data, leading to accurate data.

IfElseCloud's data lineage tracking capabilities enable organizations to trace the origin and flow of data, reducing data silos and promoting collaboration.

IfElseCloud's data privacy management ensures that sensitive data is handled carefully and tracked appropriately.

Automating production scheduling, optimizing resource allocation and minimizing downtime helps solve inefficient production processes.

Advanced analytics capabilities provide actionable insights, enabling organizations to make data-driven decisions quickly in response to changes in demand.

IfElseCloud's advanced analytics capabilities provide insights to identify opportunities for process improvement and optimize production.

IfElseCloud's root cause analysis capabilities help organizations identify the root causes of bottlenecks and inefficiencies, enabling targeted process improvement.

IfElseCloud's remote monitoring capabilities enable organizations to monitor equipment health and maintenance activities from remote locations.

IfElseCloud's features help organizations automate manual processes, increase accuracy, and identify bottlenecks in production.

IfElseCloud's automated capabilities enable organizations to identify defects early and reduce waste caused by reworked or scrapped materials.

IfElseCloud's tracking features enable organizations to track production costs at every stage of the production process, providing real-time cost information.

IfElseCloud's strategic planning capabilities enable organizations to develop and execute effective strategies that enhance competitiveness and achieve business goals.

Enables organizations to gather employee feedback and improve employee engagement, enhancing talent attraction.

Enables organizations to provide employees with opportunities for professional growth, enhancing employee development and retention.

Organizations develop a comprehensive talent attraction plan, identify key target talent, and address talent attraction bottlenecks with our MES's help.

IfElseCloud's capabilities enable organizations to share resources across departments, enhancing collaboration.

IfElseCloud's features enable organizations to optimize costs across operations, reducing manual labor costs.

Automated cost tracking enables the industry to automatically track production costs, enhancing accuracy for cost optimization.

IfElseCloud's automated reporting features enable organizations to generate reports quickly and make informed decisions, helping in solving slow decision-making challenges.

Solution for Shopfloor Workforce

Top Values for Managers

Strategic Solution for Executives

Read more about how various teams in your manufacturing can be benefited by adopting a modern Manufacturing Execution System (MES)

See all digital manufacturing prospects for your entire workforce.

Our tailored solutions for the food & beverage industry digitalize your processes and increase efficiency, providing you with a competitive edge.

Contact us to learn how we can benefit your food & beverage manufacturing operations.